Last week we went from wood to metal, from parts to systems of parts, from artisanal production to machine tool production, from pre-industry to the industrial age, Industry 1.0.

This is where Industry 2.0, or mass production, enters stage left.

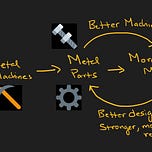

It is here where we meet our next layer of abstraction. In Industry 1.0, we put a bunch of just-alike parts together to create a machine. In Industry 2.0, we put a bunch of just-alike machines together in one place, creating a manufacturing production facility.

Of course, all the parts are interchangeable, which is one of the advantages of machine work over hand work, which is not usually appreciated.

~ Henry Ford, Today and Tomorrow, Chapter 7, What are standards?

But we didn’t stop there, oh no!

Because that would’ve just given us a bunch of single parts, carved out of chunks out of metal.

As an aside, this carving of chunks of metal is called subtractive manufacturing in the biz 👇. Learn more in just one minute in the video below; we’ll return to this concept before we’re through with our brief history.

Instead, we kept on, us intrepid makers, and we brought it all together. We needed to do more complex things than we could with just a single machined part. We needed to make assemblies 👇.

But we had done this before to make machine tools in the first place, right?

That’s right!

But as we continued to abstract the levels on which we were thinking and working every day, we continued to add complexity to not just our systems, but to our products as well.

And the complexity of products is always increasing, even today! When it increases beyond a certain point, new technology is required to actually produce at scale. Then, as Naval Ravikant says,

“Once something works, it’s no longer technology”

Such is the nature of creating. We must abstract to higher levels of challenge, of difficulty, and ultimately, of triumph; sometimes over nature itself. Sometimes with our new products.

Shout out to Orville and Wilbur Wright taking flight around the turn of the century, and also for being from Dayton, Ohio. Last time I traveled back to the DYT from San Francisco, I was actually pretty pumped to see this beautiful replica of the Wright Flyer hanging in the entry of the airport.

But let’s be real, the Wright Flyer was an artisan job.

The canonical example of making lots of exact copies of really complex things? That’s right, Henry Ford’s faster horse itself - the Model T.

In 1913, the Ford Model T became the first automobile to be mass-produced on an assembly line.

In the 19th century, Henry Ford brought this new idea of a streamlined complex system - the assembly line - to fruition, to keep pace with the complexity of what itself was a crazy complex system - the Ford Model T.

Are you feeling a bit dizzy yet from layers of complexity and abstraction? Just be happy that we can still hold everything that we’re talking about in our hands. Software isn’t all that far away in our history…

Anyways - assembly line to fruition; catapulting all of us into the second industrial revolution, characterized by "mass" production (i.e., lots of copies, one just like the other being produced). In short, Industry 2.0.

Let’s pause for a quick moment to appreciate what we just articulated.

The impact that the switch from one to many had on the subsequent two centuries literally cannot be understated.

Remember the hockey stick?

Henry Ford, for all intents and purposes of this history, in creating the system that mechanized the world, catapulted us all into the first machine age. This was the industrial revolution!

His experiments with the assembly line, while crude compared to what he would come up with later within his lifetime, also made him the pioneer of what would come to be known as lean thinking. At this stage of the game, the assembly line itself was lean thinking, albeit of the variety that scaled linearly; that is, in a straight (assembly) line.

But it also planted the seeds of many ideas that have come to have a, let’s say, mass impact, on our world today. Ideas like “Luddites” - people who are opposed to technological change - and labor unions got their start during the onset of the industrial age.

Personally, the best book that I’ve ever read on the conditions of industrial working-class folks during this time period that I think everyone should read is George Orwell’s The Road to Wigan Pier. In doing a little research for this article and series I came across a quote that I’d love to share with you, dear #unautomatable readers:

“The sensitive person's hostility to the machine is in one sense unrealistic, because of the obvious fact that the machine has come to stay. But as an attitude of mind there is a great deal to be said for it. The machine has got to be accepted, but it is probably better to accept it rather as one accepts a drug - that is, grudgingly and suspiciously. Like a drug, the machine is useful, dangerous and habit-forming. The oftener one surrenders to it the tighter its grip becomes.”

― George Orwell, The Road to Wigan Pier

When we get to digital products, I imagine that we’ll talk about the elephant in the production facility of tomorrow; artificial intelligence and machine learning. I feel ideas and analogies resonating and ruminating at the moment. Thanks, George - you seem more prescient every time I visit you.

So you can see that things are starting to get a little hairier now. With great power comes great responsibility, and as we scale the hockey stick curve as a civilization there will be many things that much change.

There will be much waste created over the subsequent 200 years, a pattern that continues to this day. The best pattern that we’ve found to counteract waste is to use only what we need when we need it, while continuously improving the way that we do things. In short; we need to work smarter, not harder. We need to run lean.

That’s what Henry Ford figured out back then too. From mass production, we follow Ford’s breadcrumbs to the next heroes of our production adventures - the great thinkers of lean manufacturing, W. Edwards Deming and Taiichi Ohno.

And with that, there is no better way to end this article than with the epic quote from the end of Ford’s epic book that Taiichi Ohno read again and again as he implemented what we would come to know as the Toyota Production System.

“We are not living in a machine age. We are living in an age when it is possible to use power and machinery in the public service - and at a private profit. But what of the future? Shall we not have overproduction? Shall we not someday reach a point where the machine becomes all-powerful and the man of no consequence? No man can say anything of the future. We need not bother about it. The future has always cared for itself in spite of our well-meant efforts to hamper it. If today we do the task we can best do, then we are doing all that we can do. Perhaps we may overproduce, but that is impossible until the whole world has all it desires. And if that should happen, then surely we ought to be content.”

~ Henry Ford, Today and Tomorrow, Chapter 24, Why Not?