Last week we talked hand tools and artisans. This week, during our foray into the historical record, we’re fast-forwarding through all of pre-history, and through most of history, to the 18th century.

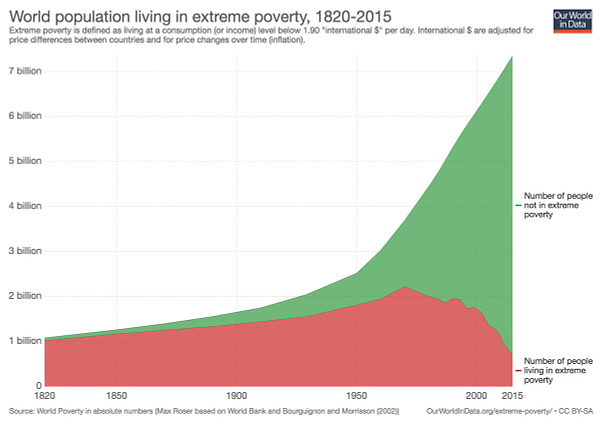

For some context, 200 years ago, about 95% of the world was poor. Like under $1/day poor.

Meanwhile, every single day from 1990 to 2015, 137,000 people were lifted out of poverty. Every. Single. Day.

So things are getting better. And check out when it started - roughly the mid-1800s!

One last fun fact before we turn back to our story.

Did you know that the most important question in economics is what the hell happened in the mid-19th century to create this hockey stick growth curve? The leading explanation appears to be that markets became more open to trading; that is, across borders, permissionlessly. In a more decentralized way, let’s say.

If that is indeed true, then the profiles of product powerhouse people who you will meet in this series are simply key figures in accelerating what those markets could - you guessed it - produce.

And, as we’ll continue to be reminded throughout this history, this black art of producing; of transforming something of lower value into something of higher value and then bringing it forth into being or existence, as it were, is central to what makes great economic engines continue to, well, produce value.

Ok, let’s bring it back down from meta land.

From Artisans to Automation

After hand tools came the first round of automation.

Wait, what? Automation?

That's right!

The first round of automation was actually moving from hand tools to machine tools.

Now, there are a lot of ways to slice this pie and throw a date on things, especially if you consider simple machine tools that helped humans figure out better ways of performing woodworking (e.g., bow drills) or creating pottery (e.g., potter's wheels) to extract more progress per unit effort (or energy put in) of human labor.

Simple machines were our first form of leverage.

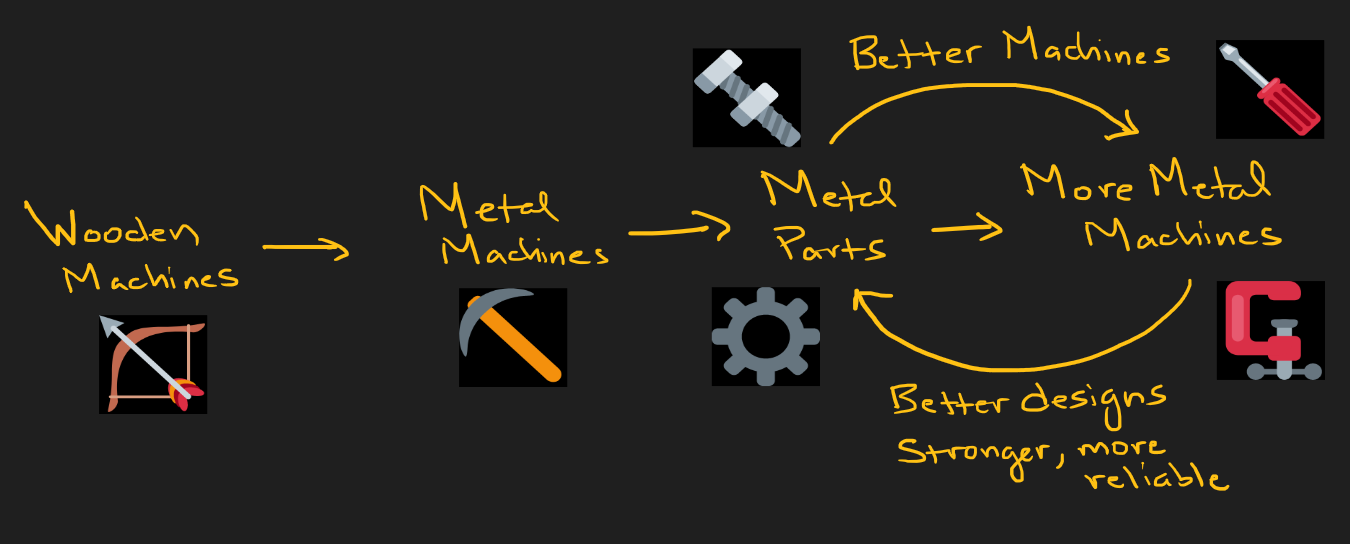

However, for the intents and purposes of this article, machine tools can be represented by the switch from mostly wooden machines to those that were mostly made from metal.

Since iron sharpens iron, once we could make a few machines of mostly metal, we could use them to process even more metal faster, cheaper, and better than before. As strength and reliability increased, so did production. A virtuous cycle of magnificent proportions, if there ever was one.

The virtuous cycle led to lots of metal machines, effectively scaling production for the first time.

Instantly, it was much easier to make exact copies of things.

Industry 1.0 was born.

Welcome to the Hockey Stick

So here we are, already automating in the 18th century.

Making stuff. Creating value. Uniformly, now.

We may have sacrificed a little flair, but we gained massive efficiencies. These new efficiencies allow humans for the first time to perform extremely complex operations with nearly perfect precision in an inexhaustible way.

Congratulations! We just performed our first product abstraction, though we have not leveraged it yet.

We’re now thinking about products made from metal that are assembled into machines made of metal, that can make both more products and therefore more machines made of metal. More generally, if we sell our machines, they are each a single product as well.

We are officially systems thinking now.

Taking advantage of this simple idea by putting it into practice (#executioniseverything), that’s what Industry 2.0, or Mass Production, is all about.

From humble beginnings and a single machine made of metal to cut metal, Mr. #unautomatable himself, the great systems thinker and philosopher of business and life, Henry Ford, did exactly that. And he changed the world forever.

Next week we’ll highlight Henry as our first great product thinker, one who was apparently born in just the right place at just the right time. Born on July 30, 1863, he left home to work as a machinist apprentice in Detroit, Michigan just 16 years later. Smart move.

Next week we - as #unautomatables who have also been born in just the right place at just the right time, no matter where we are - will not only follow Ford, but we’ll continue down our paths to the many fascinating abstractions, epiphanies, and complex systems yet to be uncovered in our brief history.

A Brief History of Product(ion), Part II: Industry 1.0, or Machine Tools 🔩⚙️